Beam Pocket

Low-pressure concrete crack injection (20 to 40 psi) permanently

fills the entire length and depth of the cracking preventing

water from further deteriorating concrete. Epoxy and

polyurethane-based materials are superior for this purpose

because they adhere to the concrete, water cannot erode the

concrete any further, and the materials allow for slight

concrete expansion and contraction while maintaining a seal.

Carbon Fiber Wall Reinforcement

Low-pressure concrete crack injection (20 to 40 psi) permanently

fills the entire length and depth of the crack, preventing water

from further deteriorating concrete. Epoxy and

polyurethane-based materials are superior for this purpose

because they adhere to concrete, water cannot erode the concrete

any further, and the materials allow for slight concrete

expansion and contraction while maintaining a seal.

Concrete crack injection has been the accepted method for these

types of repairs foe many years in the Midwest. The technique is

being adopted by an increasing amount of nationwide foundation

repair contractors because it is cost-effective, reliable and

permanent. Materials with different viscosities are manufactured

to ensure that contractors can offer homeowners an effective

repair for only hundreds of dollars as opposed to thousands of

dollars on a more extensive structural solutions.

Common

Window Crack

Common

Window Crack

Low Pressure crack injection techniques are not suitable for

repairs on larger structures such as, dams and bridges. These

require the high-pressure techniques. Epoxy crack filler

materials are most useful for repairing concrete block walls,

large cracks in concrete slabs, and filling holes left by tie

rod forms. Polyurethane materials are very useful for filling

gaps around pipes through concrete walls because they adhere

well to plastic or metal materials.

Many home owners may be tempted to use caulk or hydraulic cement

to patch concrete cracks. It would be much more expensive, but

better to go to the trouble of a structural excavation repair.

Caulk is superficial and will allow water to continue seeping

behind the patch material, resulting in efflorescence.

Eventually the water seepage will dislodge the cement plug.

Snap Crack

Waterproofing and foundation repair specialists insist they have

nearly a 100 percent success rate for crack repair work. Most

contractors offer lifetime warranties for the injection repairs

because they are confident in the product quality and the

training received from the chosen manufacturer.

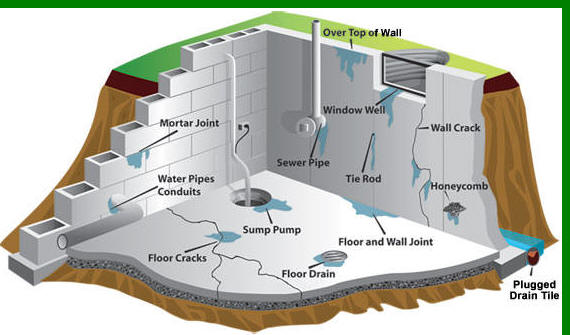

Typical Basement Layout

The majority of basement concrete cracks are formed within the

first 30 days after pouring the concrete structure. Until the

cracks begin widening, detection may be delayed. These types of

cracks often occur because insufficient amounts of working

joints were placed during construction to account for drying,

shrinkage and thermal movement. Other common cracks involve

structural settlement, overload, or earthquake damage.

Epoxy and polyurethane-based injection materials are effectively

used for concrete crack injection repair and waterproofing of

basement leaks. Supporting materials such as dispensing

equipment, surface ports, corner ports, grout injection packers,

and assorted essentials tools aid efficient injection for

fast-reacting dual component polymers.